|

wikipedia.org |

Hydrogen fuel enhancement

Onboard automotive

hydrogen injection systems inject either a

hydrogen-enriched mixture, or pure hydrogen into the

intake manifold of the engine. In some cases, this is

combined with air/fuel ratio and timing modifications. A

small amount of hydrogen added to the intake air-fuel

charge permits the engine to operate with leaner

air-to-fuel mixture than otherwise possible. As the

air/fuel mix approaches 30:1 the temperature of

combustion substantially decreases effectively

mitigating NOx production.

Increases

in engine efficiency are more dominant

than the energy loss incurred in

generating hydrogen.

This is specifically with

regard to use of a onboard hydrogen

reformer. Overall computational analysis

has marked the possibility of operating

with high air overabundance (lean or

ultra-lean mixtures) without a

substantial performance decrease but

with great advantages on pollution

emissions and fuel consumption. -

Read more

|

ArvinMeritor / MIT

on Nov. 2005 |

Hydrogen-Enhanced Combustion Engine Could Improve Gasoline Fuel

Economy by 20% to 30%

Work being done by ArvinMeritor, IAV (Ingenieursgesellshaft

für Auto und Verkehr) and MIT on enhancing gasoline combustion with a

small hydrogen gas stream is pointing toward a potential estimated

improvement in gasoline fuel economy of 20% to 30%, depending upon the

baseline engine. -

Read More |

Massachusetts Institute of Technology

Dept. of Mechanical Engineering |

Combustion lean limits

fundamentals and their application to a SI hydrogen-enhanced engine

concept

Operating an engine with excess air, under lean conditions, has

significant benefits in terms of increased engine efficiency and reduced

emissions. However, under high dilution levels, a lean limit is reached

where combustion becomes unstable, significantly deteriorating

drivability and engine efficiency, thus limiting the full potential of

lean combustion. Due to hydrogen's high laminar flame speed, adding a

hydrogen-rich mixture with gasoline into the engine helps stabilize

combustion, extending the lean limit. This work studies the fundamental

behavior of lean combustion in a spark ignition (SI) engine, identifying

the processes that determine the engine's efficiency curve, and studying

practical solutions to extend the peak efficiency and the lean limit.

Lean and hydrogen-enhanced combustion data in a SI engine were generated

covering a wide range of operating conditions including different

compression ratios, loads, types of dilution, types and levels of

hydrogen enhancement, and levels of turbulence. Combustion simulations

were then performed to quantify the components that determine the

efficiency vs. dilution curve. Results showed how burn duration is the

primary driver of lean combustion, with a limiting 10-90% burn duration

at peak efficiency and a limiting 0-10% burn duration at the onset of

rapid combustion variability. -

Read

more |

J. Eng. Gas Turbines Power

March 2008

Volume 130

Issue 2, 022801

|

Hydrogen-Enhanced Gasoline Stratified

Combustion in SI-DI Engines

Experimentalinvestigations were carried out to assess the

use of hydrogen in a gasoline direct injection (GDI) engine.

Injection of small amounts of hydrogen (up to 27% on energy

basis) in the intake port creates a reactive homogeneous

background for the direct injection of gasoline in the

cylinder. In this way, it is possible to operate the engine

with high exhaust gas recirculation (EGR) rates and, in

certain conditions, to delay the ignition timing as compared

to standard GDI operation, in order to reduce NO

and HC emissions to very low levels and possibly soot

emissions. The results confirmed that high EGR rates can be

achieved and NOx and HC emissions reduced, showed

significant advantage in terms of combustion efficiency and

gave unexpected results relative to the delaying of ignition, which

only partly confirmed the expected behavior. A realistic

application would make use of hydrogen-containing reformer

gas produced on board the vehicle, but safety restrictions

did not allow using carbon monoxide in the test facility.

Thus, pure hydrogen was used for a best-case investigation.

The expected difference in the use of the two gases is

briefly discussed.

-

Read more |

SAE International

April 2006 |

Predicting the Behavior of a

Hydrogen-Enhanced Lean-Burn SI Engine Concept

This paper explores the modeling of a lean boosted engine concept.

Modeling provides a useful tool for investigating different parameters

and comparing resultant emissions and fuel economy performance. An

existing architectural concept has been tailored to a boosted

hydrogen-enhanced lean-burn SI engine. The simulation consists of a set

of Matlab models, part physical and part empirical, which has been

developed to simulate a working engine. The model was calibrated with

production engine data and experimental data taken at MIT. Combustion

and emissions data come from a single cylinder research engine and

include changes in air/fuel ratio, load and speed, and different

fractions of the gasoline fuel reformed to H2 and CO. The outputs of the

model are brake specific NOx emissions and brake specific fuel

consumption maps along with cumulative NOx emissions and fuel economy

for urban and highway drive cycles. Model results closely match

production engine performance data for naturally aspirated

stoichiometric operation. Simulation of lean boosted operation with 20%

gasoline reformate fraction and 20% downsized displacement predicts a

23% improvement in fuel economy. Furthermore, part load engine-out NOx

emissions are reduced by 83% compared to a baseline naturally aspirated

stoichiometric production engine with 10% EGR dilution. |

|

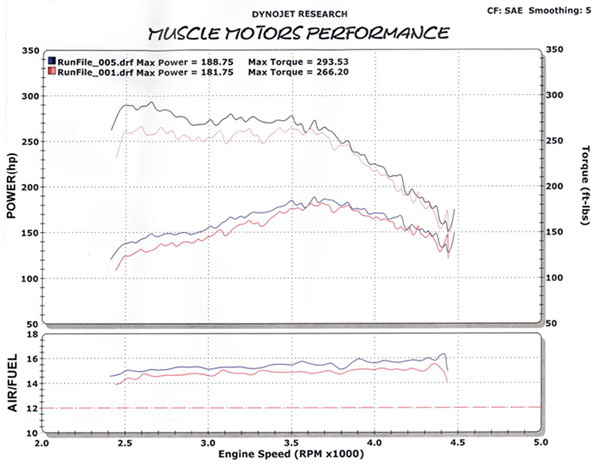

Hy-Drive

Mississauga, Ontario

May 25, 2006 |

Martinrea International Exercises

Warrants Raising $1,780,000 in Equity for Hy-Drive Technologies

LTD.

Hy-Drive is an energy technology firm that has developed a proprietary,

patented hydrogen generating system. The Hy-Drive system generates and

injects hydrogen gas into a regular internal combustion engine,

enhancing the combustion process by allowing fuel to burn more

efficiently and completely. In previous extensive customer trials and

tests, the Hy-Drive system has demonstrated significant performance

enhancements, including reduced emissions, increased torque/horsepower,

fuel savings and extended engine life. These benefits, specifically fuel

economy and reduced emissions, provide customers with greater

productivity overall, as their engines operate more efficiently, with

improved cycle times and less carbon build-up. For further information,

visit www.hy-drive.com. |

MTZ worldwide Edition

No.: 2005-10 |

Hydrogen-Enhanced Combustion - A

Promising Concept for Ultra-lean Homogeneous Combustion

Ultra-lean-burn combustion is viewed by many as a necessary next

significant step in the evolution of the gasoline engine. However,

emission constraints require that these engines operate under

stoichiometric conditions to avoid costly emissions control solutions.

The addition of small amounts of hydrogen to the cylinder charge can

allow these types of engines to operate much leaner than they otherwise

could, eliminating the need to treat NOx emissions altogether. While

this is not a new idea, it is Arvin-Meritor's development of a compact

and fast-response fuel reformer that is bringing this concept much

closer to reality. -

Read more |

|

The National Energy Technology

Laboratory (NETL), part of DOE’s national laboratory system, is owned

and operated by the U.S. Department of Energy (DOE). |

IEP

- Advanced NOx Emissions Control

Control Technology - O2

Enhanced Combustion

Oxygen-fired combustion has been utilized in industrial furnaces to

improve energy efficiency and reduce emissions. NOx emissions reductions

of as much as 80-90% have been demonstrated at commercial glass melting

furnaces that have been converted to oxy-fuel firing. One of the

required keys to successfully implementing oxygen-fired or enhanced

combustion is an economical source of oxygen, which also can benefit

numerous other technologies. Praxair is developing a novel oxygen

separation technology at its Tonawanda, New York facility, using an

Oxygen Transport Membrane (OTM). Ceramic membranes are attractive since

they can have virtually infinite selectivity for oxygen, thereby

allowing only the oxygen to pass through. There are two basic types of

ceramic membranes, pressure and electrically driven. This project will

use pressure as the driving force for separation. |

|

The World Intellectual Property

Organization (WIPO) |

HIGH COMPRESSION RATIO, HYDROGEN

ENHANCED GASOLINE ENGINE SYSTEM

High Compression Ratio, Hydrogen Enhanced Gasoline Engine System

Background of the Invention This invention relates to an engine system

and more particularly to a gasoline engine system employing hydrogen

enhanced operation.

Hydrogen addition can be

used to reduce pollution (especially NOx) from vehicles with spark

ignition engines using gasoline and other fuels. Hydrogen can be

produced by onboard conversion of a fraction of gasoline or other

primary fuel into hydrogen rich gas (H2 + CO) by partial oxidation in

compact onboard devices suitable for vehicle applications. -

Read more |

Energy Tech

October 2003

|

A plasmatron is a device

that can convert gasoline and diesel fuel into hydrogen.

Hydrogen can be used in diesel engines to reduce nitrogen

oxides (NOx) emission.

The researchers and colleagues

from industry report that the plasmatron, used with an

exhaust treatment catalyst on a diesel engine bus, removed

up to 90 percent of nitrogen oxides (NOx) from the bus’s

emissions. Nitrogen oxides are the primary components of

smog.

The plasmatron reformer

also cut in half the amount of fuel needed for the removal

process. “The absorption catalyst approach under

consideration for diesel exhaust NOx removal requires

additional fuel to work,” explained Daniel R. Cohn, one of

the leaders of the team and head of the Plasma Technology

Division at MIT's Plasma Science and Fusion Center (PSFC).

“The plasmatron reformer reduced that amount of fuel by a

factor of two compared to a system without the plasmatron.”

In gasoline engines the use

of plasmatrons will boost car fuel efficiency by 20 percent.

"If widespread use

of plasmatron hydrogen-enhanced gasoline engines could

eventually increase the average efficiency of cars and

other light-duty vehicles by 20 percent, the amount

of gasoline that could be saved would be around 25

billion gallons a year," Cohn said. "That corresponds to

around 70 percent of the oil that is currently imported

by the United States from the Middle East."

The Bush administration has

made development of a hydrogen-powered vehicle a priority,

Heywood noted. "That's an important goal, as it could lead

to more efficient, cleaner vehicles, but is it the only way

to get there? Engines using plasmatron reformer technology

could have a comparable impact, but in a much shorter time

frame," he said. -

Read more

|

|

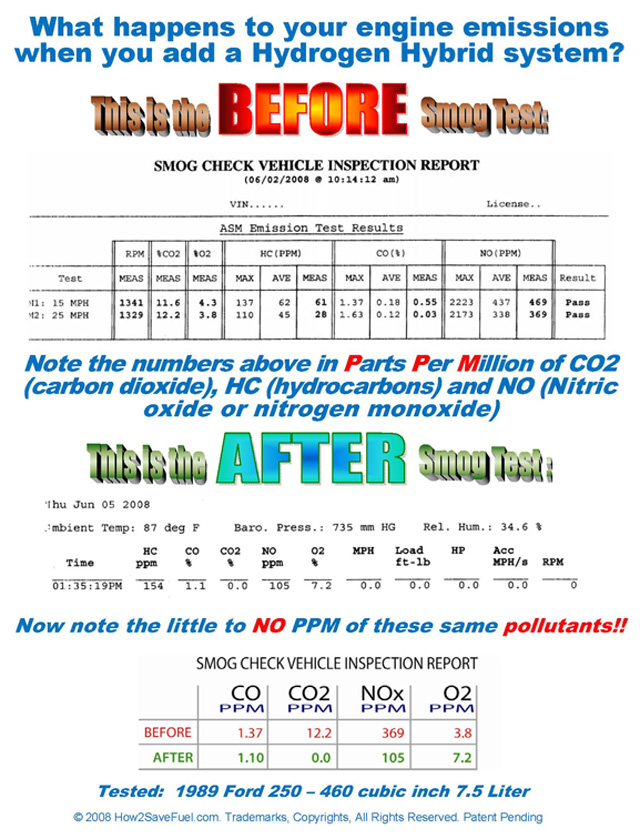

California Environmental Engineering (CEE) |

California Environmental Engineering (CEE) has tested this technology

and found reduction on all exhaust emissions. They subsequently stated:

“CEE feels that the result of this test verifies that this technology is

a viable source for reducing emissions and fuel consumption on large

diesel engines.” |

|

The American Hydrogen Association Test Lab |

The American Hydrogen Association Test Lab tested this technology and

proved that: “Emissions test results indicate that a decrease of toxic

emissions was realized.” Again, zero emissions were observed on CO

(carbon). |

|

Corrections Canada |

Corrections Canada tested several systems and concluded, “The hydrogen

system is a valuable tool in helping Corrections Canada meet the overall

Green Plan by: reducing vehicle emissions down to an acceptable level

and meeting the stringent emissions standard set out by California and

British Columbia; and reducing the amount of fuel consumed by increased

mileage.”

Additionally, their analysis pointed out that this solution is the most

cost effective. For their research they granted the C.S.C. Environmental

Award. |

|

. |

|